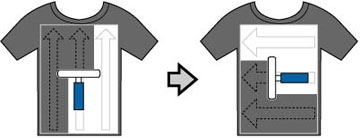

To prevent

colored T-shirt fibers on the roller from sticking to other

T-shirts, use a different roller for each color.

Note: Apply

approximately 0.5 ounces (15 grams) of pre-treatment solution to

printing areas of letter-/A4-size. Do not apply too much

pre-treatment liquid; otherwise, the print quality may decline.

Depending on the properties of the T-shirt material, traces

of the pre-treatment solution may be visible after fixing the ink

if the solution was applied using a roller. If this happens, try

applying the pre-treatment solution with a machine

instead.