After printing on a shirt, you must fix the ink using a heat press or a heat tunnel. If the ink is not sufficiently fixed, colors may come out in the wash or when rubbed.

Note: If you have

applied pre-treatment solution, we recommend washing the shirt

before wearing it.

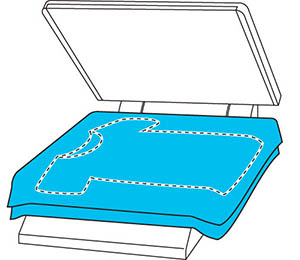

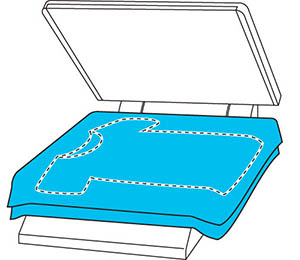

When using a heat-press, it is best to insert a heat-resistant sheet between the fabric and the heating element. When using a heat press on shirts that have plastic buttons or zippers, place a heat-resistant sheet over the buttons or zippers to prevent them from being damaged by direct exposure to the heat press.

If the printing is near the seams, such as on

sleeves, the ink may not be sufficiently fixed due to the

difference of levels in the seams. We recommend using a

heat-resistant sheet above and below the T-shirt to reduce the

difference in levels.

When using a heat press to fix ink to polyester T-shirts, the heat press can be soiled with ink due to the properties of the fabric. If necessary, clean the heat press or load a release sheet before pressing the shirt.

When using a heat press to fix ink to polyester T-shirts, the heat press can be soiled with ink due to the properties of the fabric. If necessary, clean the heat press or load a release sheet before pressing the shirt.

Fixing conditions differ between the heat press and the heat tunnel. Optimum conditions vary depending on the type of heat press or heat tunnel used and the amount of ink, so use the values in these sections only as a guide.