Since

pre-treatment machine models may vary in operation and controls,

you should consult the pre-treatment machine documentation.

Warning: Depending

on the type of sprayer used, the machine may create a mist when

applying the pre-treatment solution. Wear a mask, protective

eyewear, and gloves, and make sure the area is well ventilated. The

solution mist could also enter the printer and cause a malfunction

or damage the product. If necessary, install the pre-treatment

machine in a location away from the printer.

Note: Apply

approximately 0.5 ounces (15 grams) of pre-treatment solution to

printing areas of letter-/A4-size. Do not apply too much

pre-treatment liquid; otherwise, the print quality may

decline.

- Pour the

diluted pre-treatment solution into the pre-treatment machine as

directed by the manufacturer.

- Spread out the T-shirt on a flat

surface.

- Use sticky tape (or a lint roller) to

remove lint from the area where you will apply the pre-treatment

solution.

- Place

the T-shirt on the pre-treatment machine platen.

- Set the

controls to adequately cover the desired printed area with

pre-treatment solution. (On 1 to 100 dial controls, this may be 30

to 45.) We recommend applying the pre-treatment solution to an area

larger than the target print area.

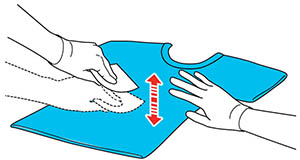

Note: You can

apply the solution evenly by running the roller over the treated

area.

- Fix the

pre-treatment solution with a heat press with parchment (silicone)

paper.

Note: The T-shirt

fibers must be pressed flat to produce even whiteness. If you use a

heat tunnel to fix the ink, use a heat press for a short period of

time at high pressure to flatten the T-shirt fibers before

printing.